Mingda MD 1000 Pro Large Format 3D Printer Professional Large Scale Industrial 3D Printer Build Volume Big Print Size 1000x1000x1000mm

Coupon: 5% Off Code MINGDA5

End Time: May 23, 2024

End Time: May 23, 2024

Mingda MD 1000 Pro Large Format 3D Printer Professional Large Scale Industrial 3D Printer Build Volume Big Print Size 1000x1000x1000mm

1000mm 1 meter large industrial 3d printer

- Premium Efficiency For Industrial 1m 3D Printing

- Extral Large Self Leveling 3D Printer Build Volume 1000x1000x1000

- Assembled & Fully Enclosed Chamber

- Two Temperature Modes To Meet Different Material Requirements

- A New Experience for High Speed 3D Printing

- Large Scale printed models the appearance of 4 to 5 times more precision than ordinary 3D printing.

- Upgraded Silent Motherboard

- Dimension(L*W*H): 1.4mx1.32mx1.93m

- Weight: 350 KG

Description

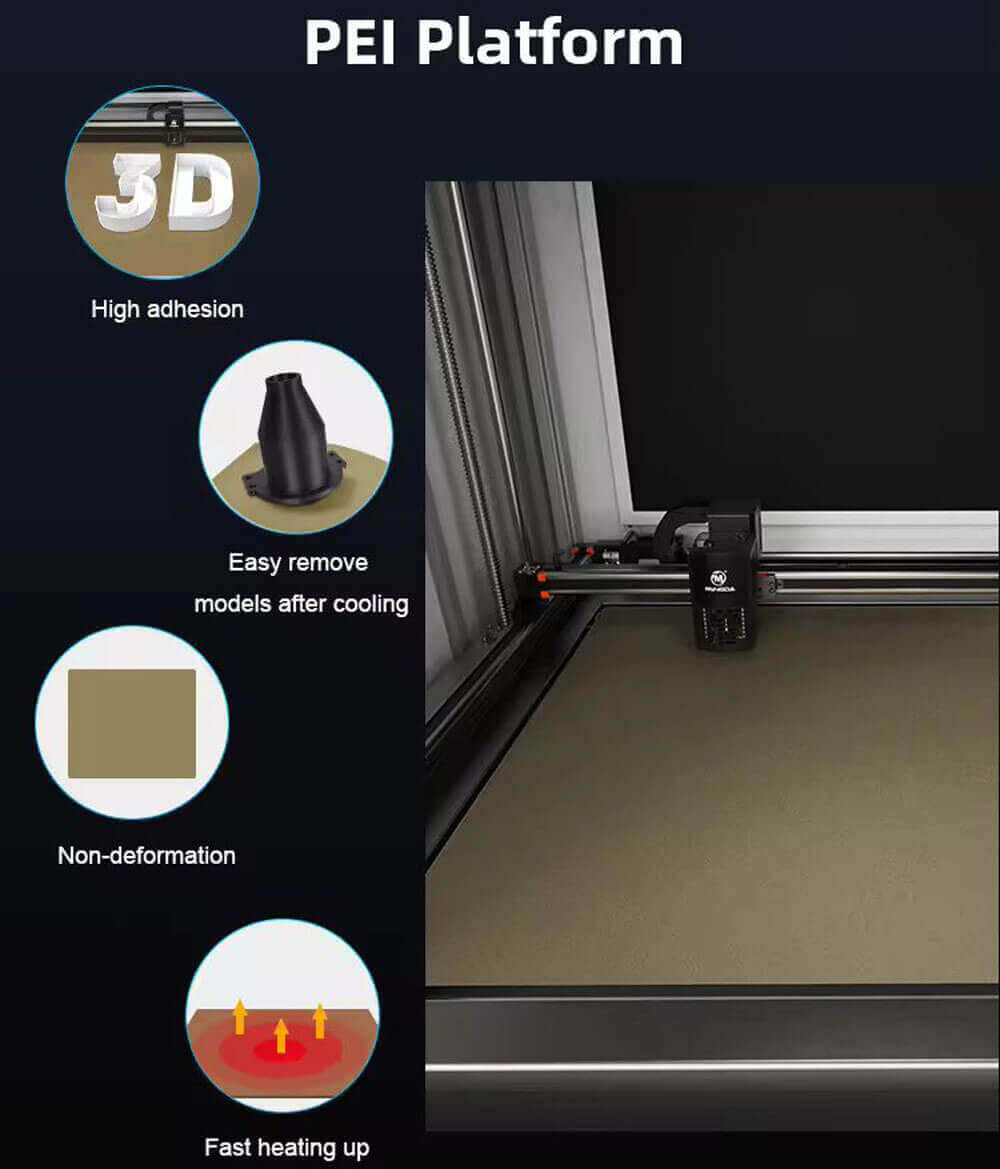

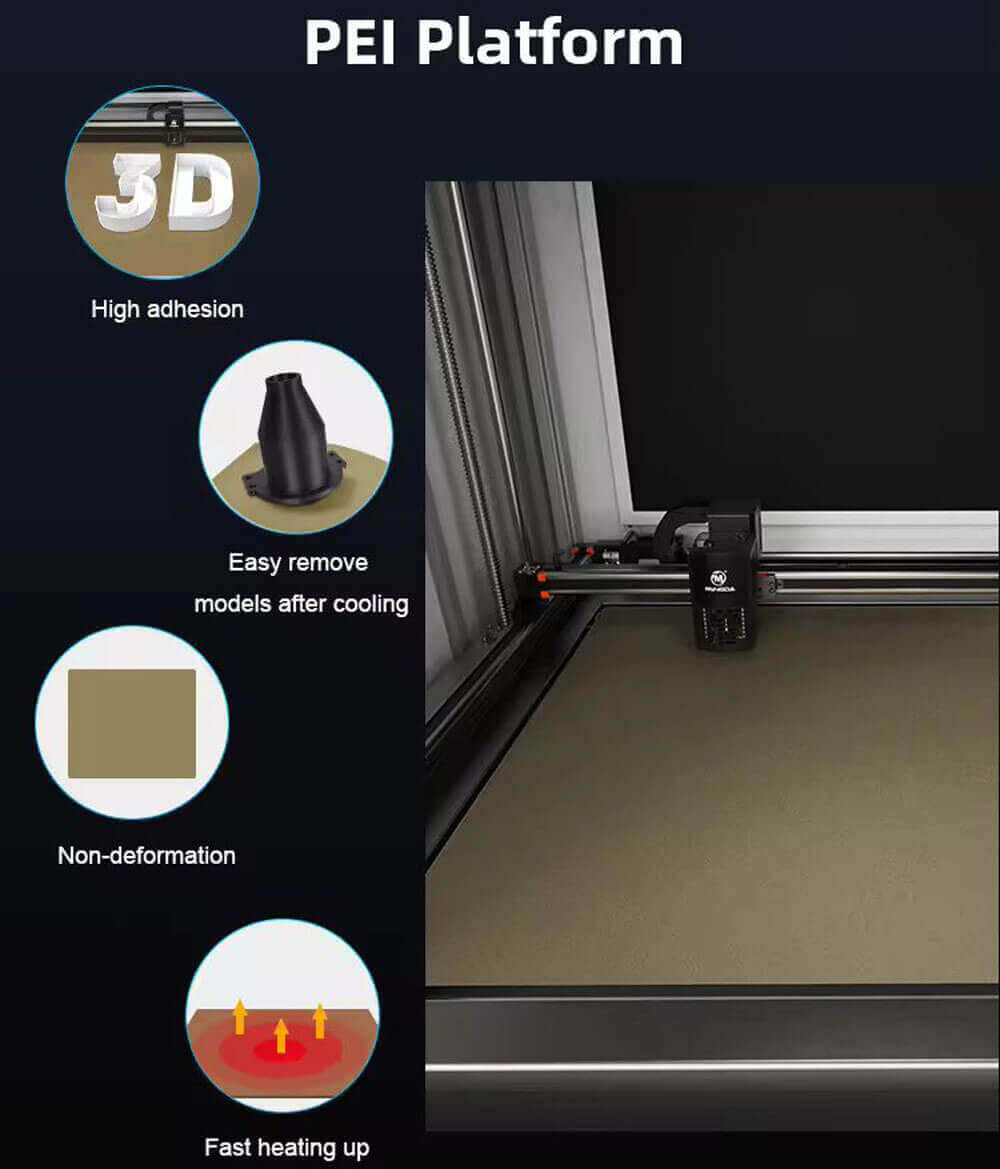

High Adhesion

Easy Remove Models After Cooling

Non-Deformation

Fast Heating Up

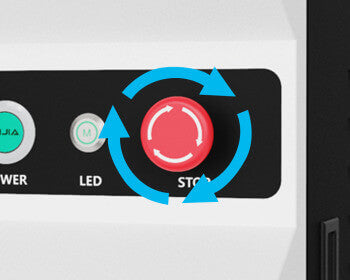

Power Switch: Industrial power button, with automatic shutdown after printing

LED Light Switch

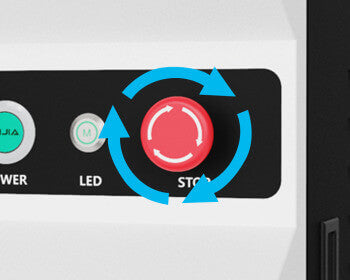

Emergency Stop Button More safe and easy to use

When a sudden power failure or filament running out occurs, the current printing task will be automatically stopped, saving materials,increasing the printing success rate and continuting your work at any time.

5 inch Colorful Touch Screen

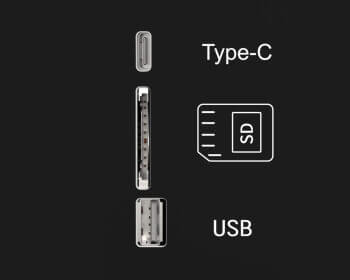

Support SD Card or U Disk Printing

Front and Rear Door Design

Closed Hanging Room

Safety Emergency Shutdown Button

Storage Box

Produce full-scale, functional parts from the alpha phase to zero series.

Learn faster and iterate designs in hours and days, not weeks and months.

Avoid expensive, outsourced, and traditional slow production.

Customize tools for perfect fit, reduced weight, and ergonomic design.

Slash lead times with on-demand production and avoid outsourcing logistics.

Reduce production and material costs of optimized tooling.

Replace high-cost patterns and molds made from expensive materials.

Speed up design iteration, product testing, and production.

Minimize outsourcing, external logistics, and supply chain dependence.

From small-series production to unique parts without added costs.

Produce on-demand to reduce inventory and warehousing.

Reduce lead times and get to market fast to stay ahead of the competition.

Continuous Innovation, High Quality Industrial 3D Printing

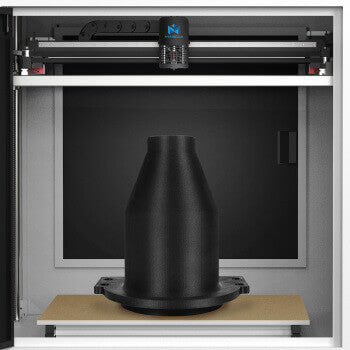

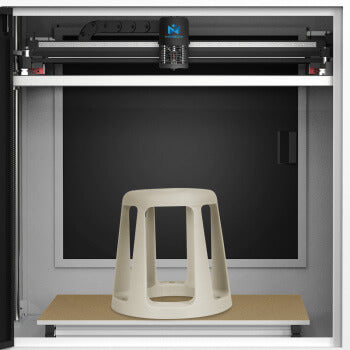

MD 1000Pro with a 1 cubic meter build volume, the MINGDA PRO is a fully enclosed industrial 3D printer for producing fullscale, large parts including functional prototypes, factory tooling, patterns and molds, and end-use parts. Built for productivity throughout all stages of manufacturing, the PRO provides designers, engineers, and manufacturers with an easy-to-use, agile solution to produce faster and cheaper.

Supported In its XY axis module structure, high precision and fast speed; Z axis four-screw, smooth and stable, MD-1000 Pro consistently provides speed, precision and quality. A new MINGDA hybrid hardware and software solution that lets you skip the hassle and start printing, the MD-1000Pro is easier than ever to use.

More And More Auto Parts Industry Uses 3D Printers To Print Sampels

Such As Front Axles, Bumpers, Seats, Etc., Which Greatly Saves Time And Cost In The Product Development Stage.

Ten Advantages

| ● Leakage Protection | ● High Speed Printing | ● Ultra Quiet | ● PEI Platform | ● Recover Printing |

| ● High Temperature Printing at 450°C | ● Oversized Printing | ● U Disk / SD Card Printing | ● ±0.1 Accuracy | ● Learn In 2H |

Two Temperature Modes

To Meet Different Material Requirements

MD-1000 Pro is a flexible, high performance and commercial industrial 3d printer. It's equipped with two types of extruders, therefore various printing needs canbe met selecting the matching module according to different types of filaments.PEI Platform

Upgraded Silent Motherboard

MD-1000 Pro uses a more powerful 32-bit motherboard independently developed by a MINGDA professional internal team.

lntelligent Design

Self Developed Slicing Software

Slices can be cut in a few minutes, easy to achieve fast printing, and achieve higher quality and more detailed printing effects. Compatible files are wider, including STL, OBJ, X3D,3MF, BMP, GIF, JPG, PNG.

Recover Printing

Printing can be continued after power-on / filament renewalWhen a sudden power failure or filament running out occurs, the current printing task will be automatically stopped, saving materials,increasing the printing success rate and continuting your work at any time.

UPS (Uninterrupted Power Supply)

Buit in UPS, When the machine is powered off, the machine will automatically suspend printing, and retum to the home point, when the power on, the machine will continue to complete the remaining printing work from the point of suspension.

Maximum Adheshion Painless Removal

Our Build Plate system completely removes scrapers and damage to 3d prints. The magnetic build plates that come with MD-1000 Pro are flexible and detachable so you can remove the models with ease.

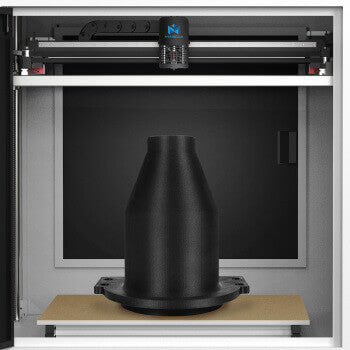

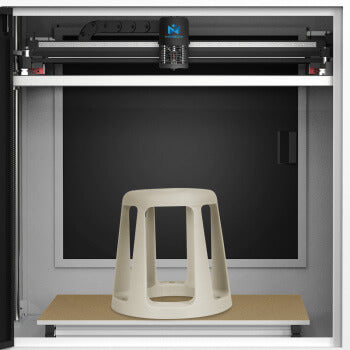

Massive Build Volume

MD-1000 Pro has massive build volume of 1000*1000*1000(mm) which enable engineers and makers to print parts in single piece.

Accurate Linear Guide Rail

Large scale printed models the appearance of 4 to 5 times more precision than ordinary 3D printing.

Innovator Of Industrial 3D Printer Auto Leveling

The interlligent leveling system can automatically adjust the uneven hotbed. High sensitivity sensor, one touch leveling and 25 points precise leveling.

Baby Step Intelligent Compensation

Baby step function is added on MD-1000 Pro During the first layer printing process, the baby step can be used for precise leveling. The control accuracy of 0.01mm makes the first layer stable and reliable and makes the leveling more intelligent.

5 inch Colorful Touch Screen

Support SD Card or U Disk Printing

Front and Rear Door Design

Closed Hanging Room

Safety Emergency Shutdown Button

Storage Box

Filament

We provide high quality MINGDA filaments. The filaments for each model are more than 72 hours, and the MD-1000 Pro is integrated with PLA large roll filaments (5kg), and there is no need to protect or replace the filaments in the middle.

HtPA-CF

HtPA-GF

PA12-CF

HtPA

PET-CF

PET-GF

PETG-ESD

TPU-Foam

Industrial Applications with the MD-1000 Pro

PROTOTYPES

TOOLING, JIGS, FIXTURES

PATTERNS AND MOLDS

END USE PARTS

Customer Model Display

The following are customer case studies in the different industry, including aircraft design, automotive design, portrait design, shoes design, automotive modification, architectural model, seat design, factory jig etc.

Parameters

| Model | MD-1000 Pro |

| Print Technology | Fused Deposition Modeling (FDM) |

| Print Volume | 1000*1000*1000mm |

| Number of Nozzle | Single |

| Layer Thickness | 0.05-0.3mm |

| Filament Diameter | 1.75mm |

| Filament Campatibility | PLA, ASA, TPU, PETG, PETG-ESD, PET-GF, PET-CF, PA12-CF, HtPA-GF, HtPA-CF |

| Nozzle Diameter | 0.6mm (0.4mm, 0.8mm optional) |

| Power Requirements | 110/220V |

| Rated Power | 2000W |

| Connectivity | USB, SD card, U disk |

| Uninterruptible Power System | Save data when power is off |

| Filament Detection | Pause printing when filament run out |

| Automatic Shutdown | Turn off the power automatically when printing is complete |

| Max. Nozzle Temp. | 350 degree |

| Max. Bed Temp. | 110 degree |

| Recommend Printing Speed | 60-100mm/s |

| Max Printing Speed | 200mm/s |

| Construction | Power Coated Steel, Aluminum Casting for Motion Components |

| Platform | PEI |

| Leveling | Auto Leveling |

| X Y Postition Precision | 0.015mm |

| Z Postition Precision | 0.0015625mm |

| Support Software | Cura, Reptier-Host, Simplify3D |

| Supported File Types | Stl, Obj, G-code |

| Operating Systems | Windows(7,8,10), Mac OS X |

Noted: The Machine equipped with one standard hot end and also one extra high temp hot end in tool box.

Download

| User Manual MD-1000 Pro | Software Windows MINGDA_Orcaslicer_v2.0.0_win64.exe |

Mingda MD 1000 Pro Large Format 3D Printer Professional Large Scale Industrial 3D Printer Build Volume Big Print Size 1000x1000x1000mm

$18,299.99